Rekluse knows that in tight, technical off-road riding, the last thing a rider wants is to lose forward momentum.

A stall is the ultimate loss of drive, and can easily lead to a crash. At best, a rider will probably have to wrestle his bike into a different position to regain enough purchase to get going again. At worst, it’s back down the hill for another try. While deft clutch control can help avoid such dilemmas, it adds to the list of things vying for finite rider attention. Even world-class riders use auto-clutches to gain an advantage.

Rekluse EXP auto-clutches employ centrifugal force to move internal parts out toward the periphery, thereby spreading the device in such a way as to close a tiny gap and press the clutch plates together. The slower the engine turns, the more those moving parts retreat toward the device center, and the less pressure is applied to the stack, ultimately leading to disengagement of the plates.

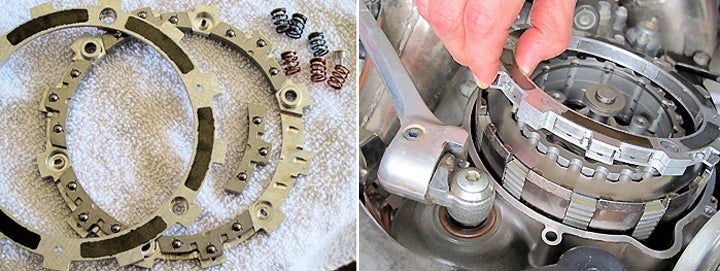

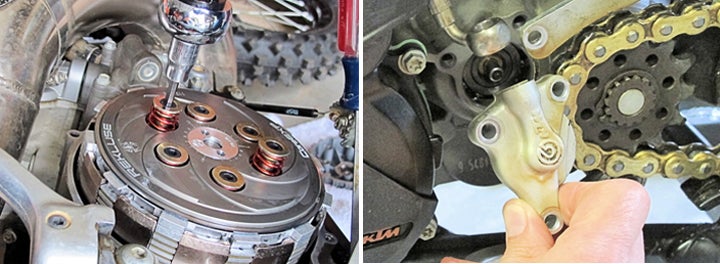

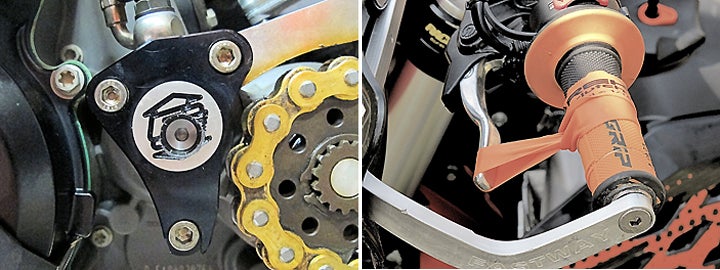

The Recluse EXP disc uses circumferential wedges sandwiched between two friction plates. Its action is tuneable through the use of different wedge shapes and different spring strengths within the device that control the rpm threshold for disengagement (these are separate from the main pressure plate springs). Compared to competitive auto-clutches, this is a particularly clever and elegantly compact design. When the wedges reach their outer limit, the EXP disc is thick enough to deliver full engagement but still thin enough that engagement can be overridden by normal lever operation.

We’ve been doing just fine off-road for many years without a clutch aid, and we didn’t like the idea of losing normal clutch control–which was what happened with earlier versions of auto-clutches that took over most/all clutch action. Rekluse’s auto-clutch, however, intervenes only at very low rpm, when a stall is imminent. Otherwise, clutch action and feel are the same as stock (well, almost –clutch pull felt slightly firmer than the stocker on our test bike). So, we still get to use all our skills, and the bike still reacts like usual to clutch popping and feathering, but we’re saved from stalling in those moments when we’re just not quick enough at the left lever.

In many situations, with the Rekluse clutch we’ve been able to run a gear taller, allowing for smoother corner exits (with less wheelspin and therefore stronger acceleration) and longer drives before a shift is required. However, this is both an asset and a potential liability. Because it’s possible to get lazy and simply ride around all day in a high gear, letting the Rekluse slip frequently to regulate power and prevent stalling, clutch plates can wear faster and be more likely to overheat. So it’s still important to use the shifter, even if you no longer have to touch the clutch lever. As long as gear selections aren’t too far from normal, a Rekluse can actually reduce clutch wear and tear because it meters out slip more precisely, judiciously and consistently than is humanly possible (or at least humanly probable).

It’s important to remember now that our bike will always feel like it’s in neutral when idling at a stop. So careless revving of the engine can result in surprising forward thrust. Doh! This isn’t really a problem; it just requires learning to use a slightly different technique. Neutral confirmation now involves more attention to feel at the shifter, and a touch of throttle instead of tentatively feeding out the clutch lever.

Another difference, which may be a big deal to some riders, is that the bike now freewheels under closed throttle; the auto-clutch eliminates engine-braking when revs drop to idle. This can be a little disconcerting at first, but like most other bike quirks, it’s something you get used to. Still, it feels “wrong” to have no engine braking with the throttle chopped, then have it return when the throttle is cracked–it’s counter-intuitive. There’s less contrast on a two-stroke, which has only mild engine braking to begin with, than on a big four-stroke, which may normally deliver ship-anchor engine braking. The ability to bump-start is also lost, but mostly rendered moot in the absence of stalling.

If you don’t want to fool with the clutch while focusing your attention on a gnarly rock garden, you don’t have to with the Rekluse. You can ignore the lever completely, and simply modulate power with the throttle, leaving the auto-clutch to slip as needed–which it does more efficiently than most human riders can. It is very, very hard, however, to break the decades-old habit of grabbing the clutch as the bike comes to a stop–or threatens to. Perhaps the worst part is how our mean, rugged woods bike now reminds us of a scooter when we take off from a standstill using throttle alone…

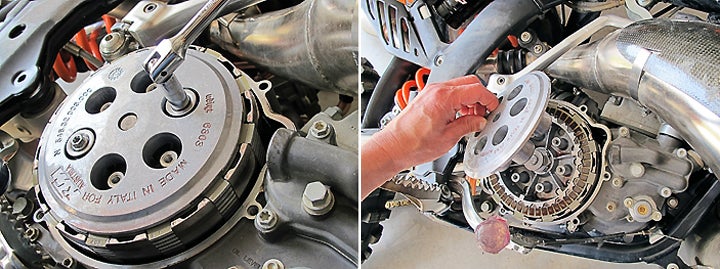

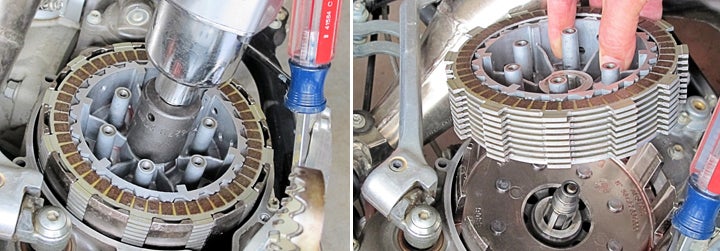

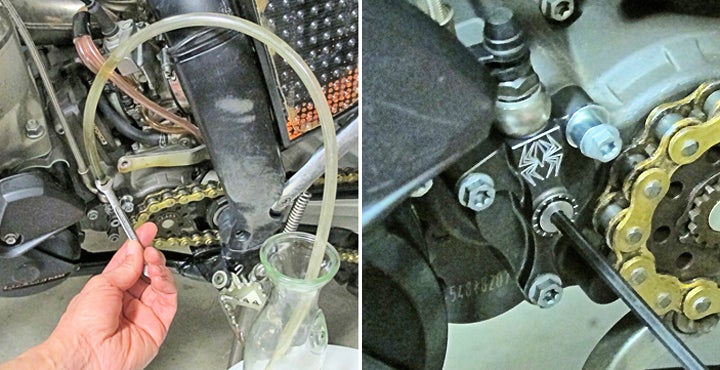

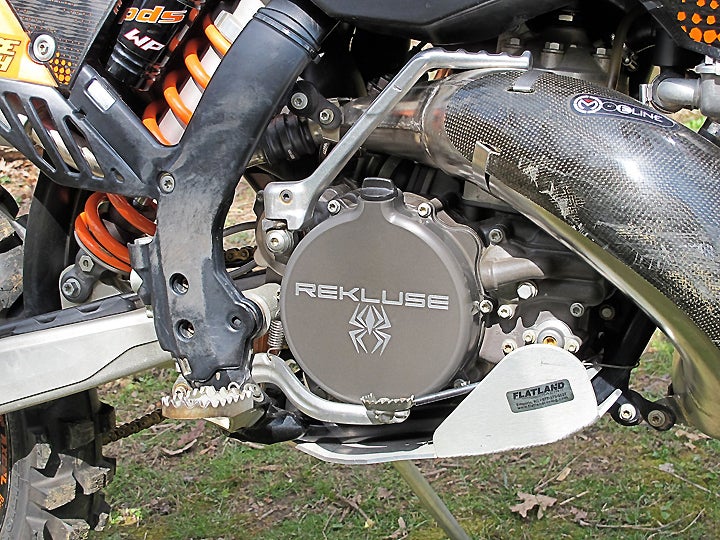

Installation of the auto-clutch was straightforward, and it is well within the capability of minimally competent home mechanics. Rekluse supplies excellent written instructions in the kit, and helpful step-by-step videos, FAQ’s and product documents are all available on the Rekluse website, along with a tech support phone number. Aside from impact and torque wrenches, we used no special tools. Everything fit perfectly, and top-shelf craftsmanship was obvious throughout. We’ve illustrated the highlights here to help you decide if it falls within your own DIY zone.

We’re quite pleased with this mod, but it is very pricey. Most casual off-roaders can tolerate a lot of stalling/restarting to save nine big ones. But more serious riders and racers will find the money well-spent. Rekluse does offer less expensive options, some of which will fit dual-sport or adventure bikes that may need all the help they can get in tough terrain. For example, the EXP disc (with new clutch springs) goes for as little as $399, and can be used in otherwise stock clutches in some bikes. Rekluse also makes manual clutch component upgrades and hand-operated rear brake setups. The latter provide an even better (much more precise) replacement for engine braking when you’re up on the pegs contending with trials-grade surfaces. Visit the Rekluse website for detailed descriptions and fitment. Rekluse covers its products with a one-year warranty on parts and workmanship, and if you don’t like their clutch for any reason, you can return it within 30 days of purchase. Contact Rekluse for pricing and availability for your particular model.

Rekluse Core EXP Clutch

Rekluse

12000 West Franklin Rd.

Boise, ID 83709

Phone: 866-735-5873

Website: www.rekluse.com

Your Privacy Choices

Your Privacy Choices