There it sat, gleaming yellow in the flickering light of two anemic fluorescent lights: my bike. Perfection. Ah yes, the satisfaction of a job well done. Here it was, noon on a Saturday, and my Sturdy Steed was ready for the race to take place on the morrow.

There it sat, gleaming yellow in the flickering light of two anemic fluorescent lights: my bike. Perfection. Ah yes, the satisfaction of a job well done. Here it was, noon on a Saturday, and my Sturdy Steed was ready for the race to take place on the morrow.

Not bad. Usually, I’d finish up around three in the a.m., catch a few hours sleep and wake up very, very tired in the morning. Too tired, in fact, to race at peak efficiency. But this week, by God, was going to be different. None of this last-minute scrambling about and bleary-eyed, late-morning work.

Nope. I’d started work on the bike on Tuesday night. Couple of hours in the garage that night on the filter and such. Then the next night, check the timing and go over all the spokes and stuff. Thursday, ah yes. Thursday, just a low-key evening in the old garage. Tune in to a funky country music station and go over nuts and bolts. No big hurry. Check all the little things. Seat bolt, air box attachments, brackets and gidgets ‘n things. Nothing was left to chance.

Friday was like frosting on the cake. Take apart the carb and check for sediment, blow out the petcocks and peek in the fuel line filter — oh yes — even check the gearbox oil level and change fork oil. Like I said, by Saturday morning, every¬thing was well under control.

There sat the mighty flyer, a finely honed package, waiting for the master to sling a leg over the saddle and bloot off into the open spaces. Reward time!! I popped open a cold can of suds and leaned back against the work¬bench, giving silent thanks that I had the foresight to work in advance. None of this last-minute crap for me anymore. Nosirree. Get it done early and get to bed early that night. Clean mind, clean body, and a well rested knight faces the morning jousts with impeccably prepared and efficient organism.

Let’s see… was there anything at all that I had missed? I mean, as long as I was standing there, it never hurts to check for that last little detail. Lemmmee look… hmmmmm… cables lubed, filter serviced, fresh plug, everything good and tight, all the motor mount bolts gone over… erp!!! Wait a minute! That bottom motor mount bolt, the one under the skid plate. That’s the one item I never did check. Wow. It’s a good thing the old memory banks clicked into high gear. Man, if that thing ever got loose, the 501 would shake like a one-legged washing machine on the spin cycle. Whew. Damn good thing I thought of it.

Let’s see… was there anything at all that I had missed? I mean, as long as I was standing there, it never hurts to check for that last little detail. Lemmmee look… hmmmmm… cables lubed, filter serviced, fresh plug, everything good and tight, all the motor mount bolts gone over… erp!!! Wait a minute! That bottom motor mount bolt, the one under the skid plate. That’s the one item I never did check. Wow. It’s a good thing the old memory banks clicked into high gear. Man, if that thing ever got loose, the 501 would shake like a one-legged washing machine on the spin cycle. Whew. Damn good thing I thought of it.

No big deal. Just remove the skid plate and get a pair of 13mm wrenches on the offender. Snug ‘er up, and call it a job well done.

It took, oh, maybe 20 minutes to get the skid plate off. Not such a long time, considering that about $20 worth of Loctite was holding the nuts and bolts in place. I really did not want the plate to fall off. I re¬member the one time a skid plate of mine did fall off… but I’d rather not go into that story at this time.

Seeing as I was in clean street clothes, a section of the daily newspaper was laid on the oil-mottled floor to prevent discoloration of Sears especial $3.99 chinos. Ah hah! The offending nut was indeed loose on the bolt. ‘Tis a good thing I had the foresight to follow every detail through to its conclusion. Preparation pays, ya know.

One 13 wrench on the bolt and the other on the nut soon got the proper tension… just one more turn… perhaps one more for insurance… PING!!! Dammit! Snapped the bolt in half. Curses filled the air. The resident pussycat slunk off into the bushes as blasphemous Navy curses crackled at 143 dbs on the A scale. Double damn and many shucks, not to mention a smattering of gee whizzes, emanated from my normal altar-boy-like mouth.

A quick study of the situation left me no alternative. Without that lower motor mount bolt, the 501 would surely shake itself to dust in less than five miles. But to replace that offending unit would mean yanking the engine. The man who designed the piece of apparatus immediately became the recipient of many evil thoughts, and most certainly would have received bodily injury if he had been present.

Oh well. At least I still had plenty of time left in the day to make a repair to that one stupid bolt. Forty minutes later, the engine was sitting on the floor, right next to the exhaust pipe and the carb and the coil and the head steady. The bleak hole in the chassis stared back at me, as if to say, “You dumbass, you should have known better than to trust one of those hardened peanut-butter bolts.”

Mumble, mumble.

A search through the Official Dirt Bike Trick Toolbox revealed the non-presence of the right sized bolt. Oh, there were longer ones and shorter ones, but not one of the correct thickness and length.

More mumble mumble.

So I fired up the truck and headed for the nearest Maico shop, Mike Chamberlain’s, about two miles away. Sure, Mike had one, and that’ll be 86 cents puhleeeze and here’s your receipt and y’all hurry back, hear?

I flipped the bolt up on the dash of the truck, and smoked off (literally) down the street. Sheer moments later, I arrived at the garage, and reached up on the dash for the bolt. Heartsink! It had fallen down the crack between the dash/window joint. I clambered up on the hood of the El Camino and peered in through the windshield at the offending gap in General Motors’ finest effort. With much neck craning, I was able to spot the wayward bolt about five inches down under the dash, nestling on a rat’s nest of wiring. A quick check from the floor of the truck revealed that it would be impossible to reach the bolt from underneath.

Back down the road towards Chamberlain’s shop, the throaty exhaust of the truck splitting the tranquil San Fernando Valley air. I hurriedly whipped into the parking lot and leaped out of the truck for the door. Which was locked. A sign on the glass proclaimed, “GONE RACING – SEE YOU NEXT WEEK.”

Aaaarrrgh!

The balance of the afternoon was spent flitting all over town looking for the right kind of bolt in one bike shop after another. Zero over zero luck. You see, it has to be this one certain size; nothing else will do. Faced with the possibility of twittering away the rest of the day on L.A. freeways, I headed back for the garage and proceeded to do the only logical thing. Off came the windshield of the truck and the bolt was rescued. And it only took about three hours. Feverishly, I ran into the garage and started to install the bolt in its proper place on the chassis.

Whaaaaat? Oh no! It was the wrong bolt. This one was far too thick, even though it was the right length. Now what? Enough was enough. I would have no more of this hunting-around trash. I would make the bolt fit, come hell or high water. Out came the big electric drill and the right sized bit was placed in the chuck.

Now, at this moment in time, you would think that the fates would have backed off and left me alone for the day. No way. The drill bit sunk in the hard chrome moly metal and chewed a path out, then snapped cleanly off at the hilt, leav¬ing a free-wheeling electric drill to buzz its buns off for naught. Curse of curses!

Oh well, there was always the chance that an EZ-out would extract the drill bit. Sure. Did you ever try to drill a hole in a drill bit? No way; a half-dozen ruined bits lay on the floor some hours later, exuding smoke and round edges.

Wait a minute; there in the corner of the garage sat the old original prototype 450 Maico, complete except for head and barrel. Heh, heh.

I would merely take that chassis and install the 501 engine in it. I would ride tomorrow. It made sense; the two chassis were virtually identical.

The key here is the word “virtually.” Never, never in a zillion years, would you suspect how much diffi¬culty a one-inch variation in pipe brackets can cause. Out with the torches, the hacksaw and …

At 5:30 that next morning, Tom’s van lumbered into the driveway. The sight that greeted his sleepy eyeballs must have been something indeed, here, spread over the garage and all over the driveway, were the following: Two motorcycles, completely disassembled, the windshield of the truck leaning against the fence, a pile of beer cans around the bike propped up on the stand, tons of tools scattered about, and one each person who had been working all night and still wasn’t done.

“Well,” said Tom, “are you going racing or are you gonna rebuild your entire garage this morning?”

Feverishly, I glanced around at the carnage. At best, it would take another full two hours to finish my bike. But then, the race was about 90 miles away and that would give me plenty of time to work in the back of the van while Tom was driving. We loaded all the necessary trash in the van and boogied off down the road… in-between munches of a McDonald McTriple Burger, I continued turning wrenches.

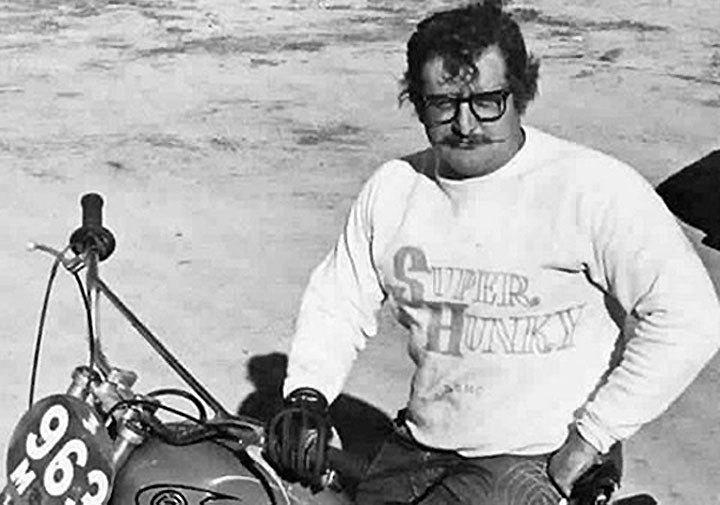

Right about halfway to the track, Tom leaned over the seat and sarcastically asked, “Hey Rick, howcum you didn’t take care of all this stuff earlier in the week? I had my bike completely done Saturday morning, ya know, you really ought to…”

A tear splattered against the backing plate. It was mine.

Your Privacy Choices

Your Privacy Choices