Chances are this has happened to you. You’re riding along and something falls off your bike. Or even worse, something comes loose and jams up your riding system. Take it even further. Your bike locks up and spits you over the handlebars. Not much fun, is it?

Right about this time, you wish you had made sure everything was tight on your bike. Even better, maybe you could have done something to keep it from coming loose.

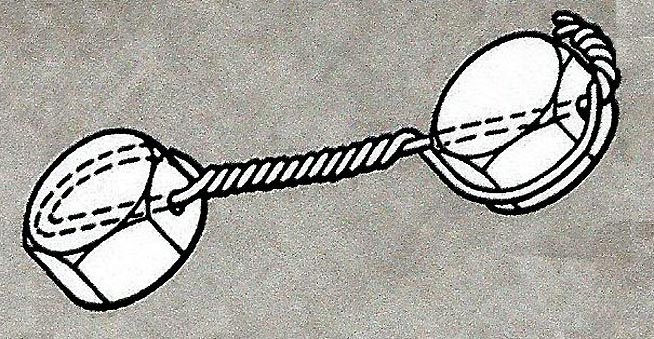

You want to drill your own, there are a number of kits on the market to make the job easier. They usually consisted of adjustable holder is small hardened drill bits. Most of them are worth money. Some are simply junk. The job is much easier was a good pair of safety wire pliers. Demonstrate to our is 0.032 inches in diameter, and a strong enough for a fixture on a motorcycle. Never reuse old safety wear. You can never tell when it has been twisted past the safe point and is ready to break. Fresh wire is so cheap, there is no excuse to reuse the old stuff.

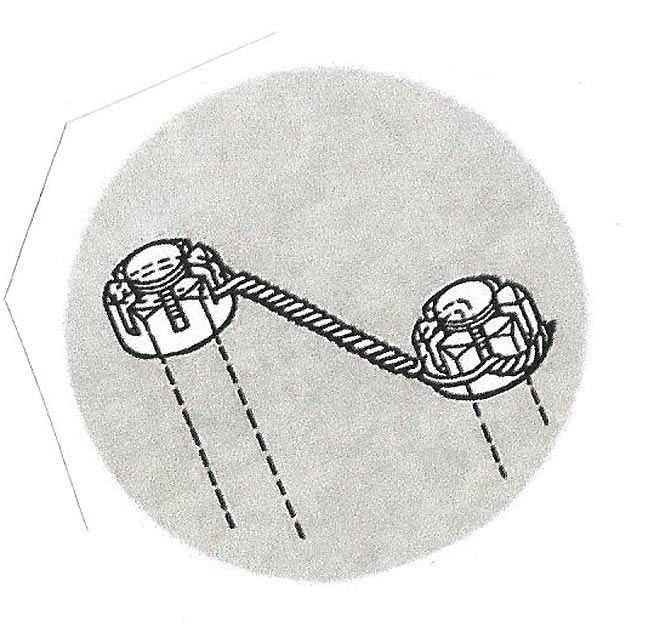

Lines should be placed so that loosening of the nut or bolt will tend to tighten. All nuts or bolts should be clean when installed, or they may loosen when the dirt or rust is present. Some of the nuts and bolts must be torn down to certain specified levels. Check your workshop manual for your particular bike.

Here is where a little common sense and judgment is needed. Let’s say the specified poundage is 45 foot-pounds. Tighten to approximately 40 lb-ft., then bring the slot around to have the hole line up. Do not hit 45 lb.-ft. then back off searching for the line up point.

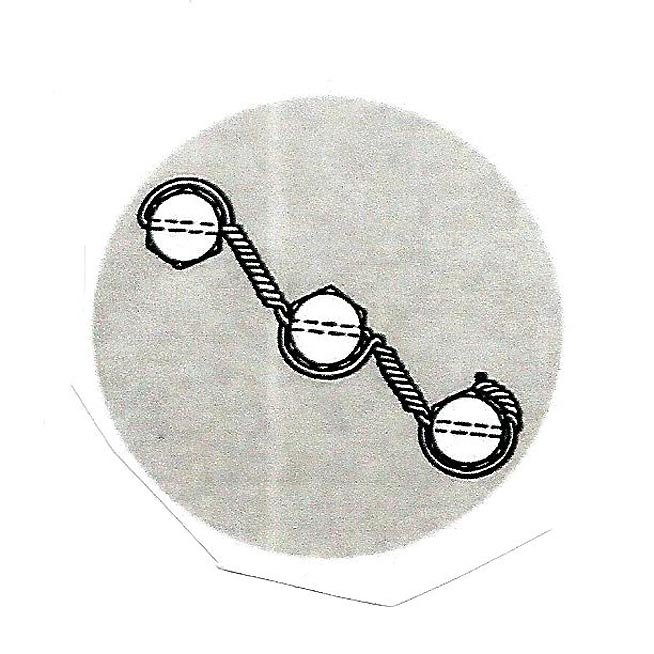

In a very critical situation, use castellated nuts interconnected with a double twist wire. Whenever possible, use a double twist method. If the nuts are fairly close together, they may be connected to each other. If they are far apart, they should be individually secured to another surface.

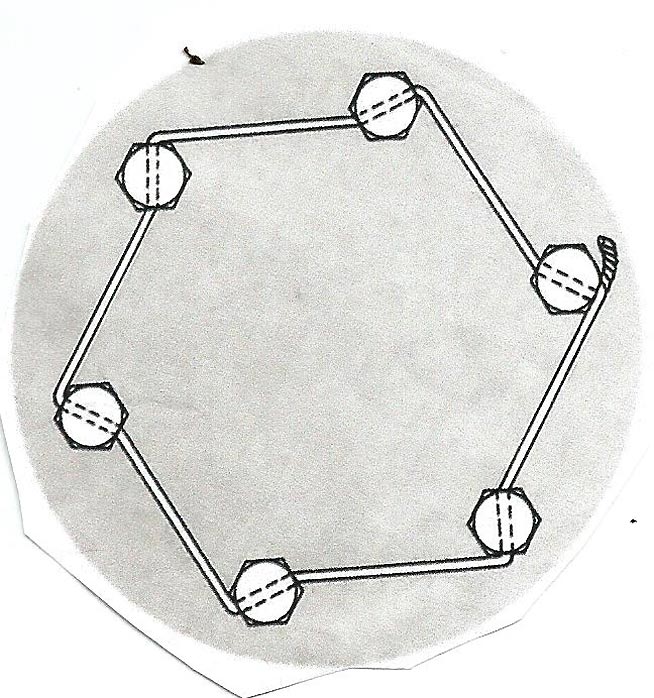

One of the most critical areas on a motorcycle is the rear sprocket. Nothing else has much abuse or stress. The illustration with six bolts shows the correct pattern to use. Any close cluster of nuts or bolts can be joined in this fashion. Some people run the loop of the same to our over-the-top available, but we feel this is less desirable than running to one side. It should be run over the side and twisted in the direction of the thread rotation. In other words, it might be twisted clockwise for the right hand threads and counterclockwise for left hand threads.

Don’t over tighten. That’s a very important role. Check for slop in the direction of the twist, and bend the left over wire in and out of the way. Failure to do this can cause a rip in expensive leathers or less expensive, but more painful, skin.

Your Privacy Choices

Your Privacy Choices